Surface Preparation

Wood surface must be clean, dry and frost-free (moisture content max. 18%).

Osmo Spray-Wax is ready to use. Do not thin. Stir well before use.

Clean old microporous stains thoroughly. Old paints and lacquers must be completely removed. As a general rule, wear a dust mask during sanding works. Fill small cracks, larger joints or holes in wood (with Osmo Wood Filler). Sand wood surfaces carefully. Begin with coarse sandpaper – final sanding work for flooring grit P 120-150, for furniture grit P 220-240.

Before oiling the surface, remove sanding dust with a broom or vacuum cleaner.

The finished surface is influenced by several factors, including the condition of the wood. Therefore, a trial application is always required, especially for unfamiliar surfaces.

Method of Application

Spray Wax is ready to use. Stir well before use

1. Coat: with cup spray gun, RP Technology or Airless/Airmix Application amount is, among other things, dependant on the wood species and sanding grade etc, approx.

35-40 g/m² (3010 Natural 20-25 g/m²). Allow for good ventilation whilst drying.

Inbetween sanding/de-nibbing: min: P220 sanding grit

2. Coat: with cup spray gun, RP Technology or Airless/Airmix Application amount is, among other things, dependant on the wood species and sanding grade etc, approx.

35-40 g/m². Allow for good ventilation whilst drying.

The second coat after applying Spray-Wax 3010 Natural depends on the desired surface results (trial application):

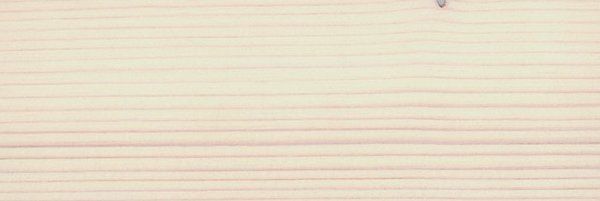

a)Top coat with Spray-Wax 3010 Natural for a slightly white colouration.

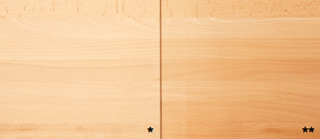

b)Top coat with Spray-Wax 3084 Clear for a “like untreated” look.

Osmo Spray-Wax can also be applied with a brush or cloth.

Spray parameters:

Cup spray gun: Spray pressure approx. 2,5 – 3,5 bar, Nozzle approx. 1,3 – 2,0mm.

RP (Reduced Pressure) Technology: Spray pressure approx. 1,6 – 2,0 bar, Nozzle approx. 1,6 – 1,8mm.

Airless/Airmix: Depending on the operation of the operator/machine, the equipment and the condition of the respective system as well as the type and shape of the workpieces to be treated.

The large variety of application tools/possibilities with this system make it unrealistic to create guidelines.

Note

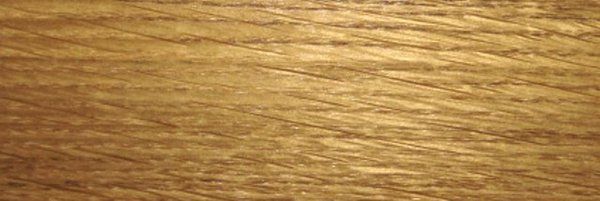

Clear Spray-Waxes enhance the natural tone of wood (permanent wet effect). For cabinet interiors and drawers, apply max. one coat thinly with a cloth. For a colour treatment, Osmo Oil Stain is ideal – just apply as a base coat. For dark woods and hardwoods rich in extractives (e.g. Wenge, Merbau, Jatoba etc.), we recommend using Osmo Wood Wax Finish Clear Extra Thin or Polyx®-Oil 2K PURE. A trial application is recommended.

Wood surfaces treated with Spray-Wax are easy to maintain. Remove debris with a broom or a vacuum cleaner. For cleaning, add Osmo Wash and Care concentrate to mop water and clean the surface with a damp (not wet!) mop. For refreshing and intensive cleaning, use Osmo Liquid Wax Cleaner when necessary. If a higher gloss level is desired, after thoroughly drying apply Osmo Liquid Wax Cleaner thinly and polish when dry.

Using general or multi-purpose cleaners will increase the frequency of maintenance and recoating. Allow finish to fully cure before heavy usage.

Care

Regular Cleaning: Dust mopping using the green Dust-Mop from the Osmo Mop Cleaning Kit for Floors. Damp mopping using Osmo Wash and Care or Osmo Spray-Mop.

Occasional Maintenance:

Intensive cleaning and refreshing using Osmo Liquid Wax Cleaner or Osmo Maintenance Oil.

Recoating:

Simply re-apply one coat onto the clean and dry surface when signs of wear become visible.